Cross Reference Look-Up

Full Site Keyword Search

Cross Reference Look-Up

Menu

The Toyota 2H engine is an old girl by today’s standards, but this popular engine from the 1980s was used in Landcruisers, Dynas, Coaster Buses, and many industrial applications. It may be an engine that is over 30 years old, but there are still quite a few getting around, and there is a technical issue that owners should be aware of.

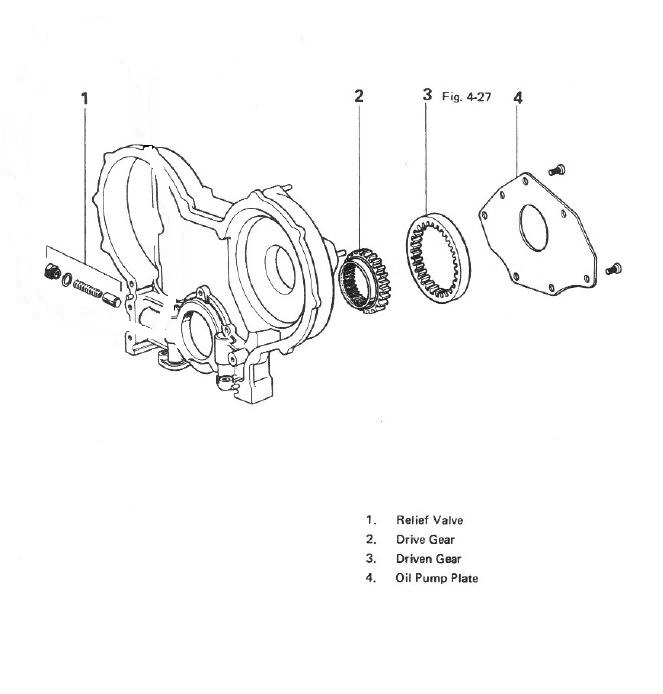

There is a pressure relief valve that is located near the oil pump, which can get stuck due to debris or general wear & tear, which can cause a pressure spike in the system. This may cause the oil filter to expand and even fail in some circumstances. It is easy to blame the filter as the part that has failed, and from outward appearances, this is exactly what it looks like, but the cause of the failure is not the filter but a faulty pressure relief valve. The pressure relief valve may seem to be okay from an outward inspection, but it is the cause of most failures of this kind.

To resolve this issue, you will need to either clean or replace this pressure-release valve.

This affects the following filters: AF1633, 15601-68010, Z161X, MZ161X, WZ161X, BT221, P550707 & LF3399

See below for the official notice from the manufacturer.

“Spin on type oil filters are designed to withstand oil pressures considerably in excess of the highest working oil pressures specified for modern engines. Engine manufacturers typically require that the oil filters withstand minimum pressures of 200 P.S.I. or over twice the normal operating oil pressures of most engines. In spite of these large safety margins, filter over pressurization and subsequent engine damage can and does occur; invariably as a result of a malfunction of the engine’s oil pressure regulating valve. This valve is installed either as part of the oil pump assembly or less usually at an oil gallery location downstream of the oil filter. Its function is to control maximum oil pressure in the lubrication system and its operation is crucial in modern high-speed oil pumps and engines. In the event of unregulated oil pressure, any spin on oil filter will fail, beginning with the deformation of its body or shell and leading usually to eventual seal blow out. It is interesting to note that the release of system pressure occasioned by filter leakage or blow out may temporarily free the malfunctioning pressure regulating valve and thus give cause for the suspicion that the filter was faulty. Known causes of oil pressure regulating valve failure are as follows:

DIRECTION PLUS

DIRECTION PLUS DIRECTION PLUS

DIRECTION PLUS DIRECTION PLUS

DIRECTION PLUS